You might think electric cars don't need radiators since they lack traditional engines, but you'd be surprised to learn they actually do. Unlike conventional vehicles, electric cars use radiators to cool their batteries, power electronics, and electric motors. Efficient thermal management is essential for these components to prevent overheating and guarantee peak performance. Curious about how these systems work and why they matter for your electric vehicle's efficiency and longevity? There's a lot more to uncover about the intricate cooling technologies that keep your EV running smoothly.

Contents

Importance of Thermal Management

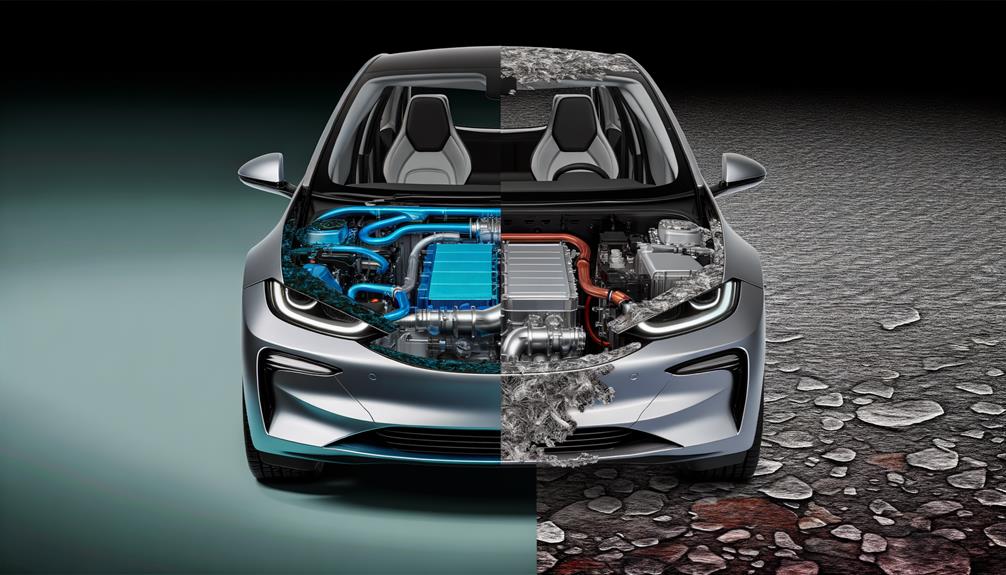

In electric vehicles, thermal management systems are vital components that directly influence the performance, reliability, and lifespan of key elements such as battery packs, power electronics, and motors. These systems work to maintain ideal temperatures, typically between 20 to 45 degrees Celsius, which is essential for guaranteeing the safety and efficiency of lithium-ion batteries. If the battery pack overheats, it can lead to thermal runaway, posing significant safety risks and reducing the overall longevity of the battery.

Effective thermal management strategies are necessary to prevent the degradation of battery life and driveability due to excessive heat generated during operation. Advanced cooling systems, such as liquid cooling, play a pivotal role in maintaining these perfect temperatures. By circulating coolant around the battery pack and other critical components, these systems dissipate heat more effectively than traditional air cooling methods. This guarantees that the battery pack remains within its ideal temperature range, thereby maximizing charging speed and prolonging service life.

The adoption of sophisticated cooling technologies is a demonstration of the industry's commitment to enhancing vehicle efficiency and performance. For instance, direct oil cooling for inverters exemplifies how targeted thermal management can lead to notable improvements in component reliability and overall vehicle performance. By directly addressing the heat generated by high-power electronics, these cooling systems help maintain stability and performance under varying operational conditions.

As electric vehicles continue to evolve, ongoing research into optimizing thermal management systems will be vital. Overcoming challenges related to system complexity and performance benefits will guarantee that future EVs are more efficient, reliable, and capable of meeting the demands of modern consumers.

Battery Cooling Systems

Shifting the focus to battery cooling systems, these mechanisms are essential for maintaining the ideal operating temperature of lithium-ion batteries in electric vehicles (EVs). The primary method employed is liquid cooling systems, where a coolant mixture, typically composed of water and ethylene glycol, circulates through the battery pack. This process is vital for absorbing and dissipating the heat generated during charging and aggressive driving.

Maintaining the battery temperature within the optimal range of 20 to 45 degrees Celsius is critical. If the temperature exceeds this range, the risk of thermal runaway increases, which can lead to catastrophic failures and potential hazards. Consequently, efficient battery cooling systems are not just a matter of performance but also safety.

Comparatively, some EV manufacturers utilize air cooling systems, where cabin air is circulated around the battery pack. However, this method is generally less efficient, particularly in hot climates, making liquid cooling systems the preferred choice. The liquid coolant's superior heat transfer capabilities guarantee that the battery remains within the safe operating temperature range, thereby enhancing the overall performance and lifespan of the battery.

Effective battery cooling systems directly influence the vehicle's driving range and charging efficiency. By maintaining optimal temperatures, these systems guarantee that the battery can deliver consistent power output and accept high charging rates without degradation. This not only improves the vehicle's immediate performance but also prolongs the battery's life, offering long-term benefits to the user.

Power Electronics Cooling

When considering the heat management strategies for electric vehicle power electronics, you'll find that effective component temperature control is paramount for system reliability. Liquid cooling methods, using a coolant to dissipate heat from inverters and converters, are commonly employed to maintain ideal operating temperatures. Advanced technologies like direct oil cooling are also emerging, offering enhanced heat removal and simplifying thermal management designs.

Heat Management Strategies

Power electronics in electric vehicles, such as inverters and DC-DC converters, generate substantial heat that necessitates advanced cooling strategies to guarantee peak performance and prevent failures. Effective thermal management systems are essential for maintaining the efficiency and reliability of these power electronics.

To manage the excessive heat, liquid cooling systems are often employed, utilizing specialized coolants to efficiently absorb and dissipate heat during energy conversion processes. One emerging technology is direct oil cooling, which not only enhances heat removal but also provides lubrication for moving parts in the electric drivetrain.

Consider the following key strategies:

- Liquid cooling methods: Using specialized coolants to absorb and dissipate heat.

- Direct oil cooling: Enhancing heat removal while lubricating drivetrain components.

- Thermal management systems: Ensuring control and efficiency, preventing overheating.

- Innovative cooling technologies: Aiming to simplify systems and improve performance.

- Reliability and efficiency: Maintaining peak performance by preventing control glitches and catastrophic failures.

Proper cooling of power electronics is vital. Overheating can lead to control glitches, reduced efficiency, and potentially catastrophic failures, which greatly impact the overall reliability of the vehicle. Continuous advancements in thermal management aim to simplify these systems while enhancing their performance and efficiency, driving the evolution of electric vehicles forward.

Component Temperature Control

Effective component temperature control in electric vehicles is essential for ideal performance and longevity. Power electronics, such as inverters and DC-DC converters, generate substantial heat during operation. To prevent overheating and guarantee reliability, these components require efficient cooling solutions.

A common method involves liquid cooling systems, which utilize special coolant mixtures to effectively dissipate heat. This cooling loop maintains ideal temperature ranges, vital for avoiding control glitches and component failures, thereby safeguarding vehicle performance and efficiency.

Recent advancements are exploring direct oil cooling, which simplifies thermal management and boosts overall system performance. Continuous monitoring and management of power electronics temperatures are necessary to prolong the service life and maintain high fuel economy in electric vehicles.

Here's a comparison of different cooling methods:

| Cooling Method | Advantages | Challenges |

|---|---|---|

| Liquid Cooling | Efficient heat dissipation | Complexity in design |

| Direct Oil Cooling | Simplified thermal management | Potential for oil degradation |

| Air Cooling | Cost-effective | Less efficient for high power |

| Phase Change | High efficiency | Expensive and complex |

| Hybrid Systems | Enhanced performance | Increased system complexity |

Maintaining precise temperature control through these methods guarantees the longevity and reliability of power electronics in electric vehicles, ultimately enhancing overall vehicle performance.

Electric Motors Cooling

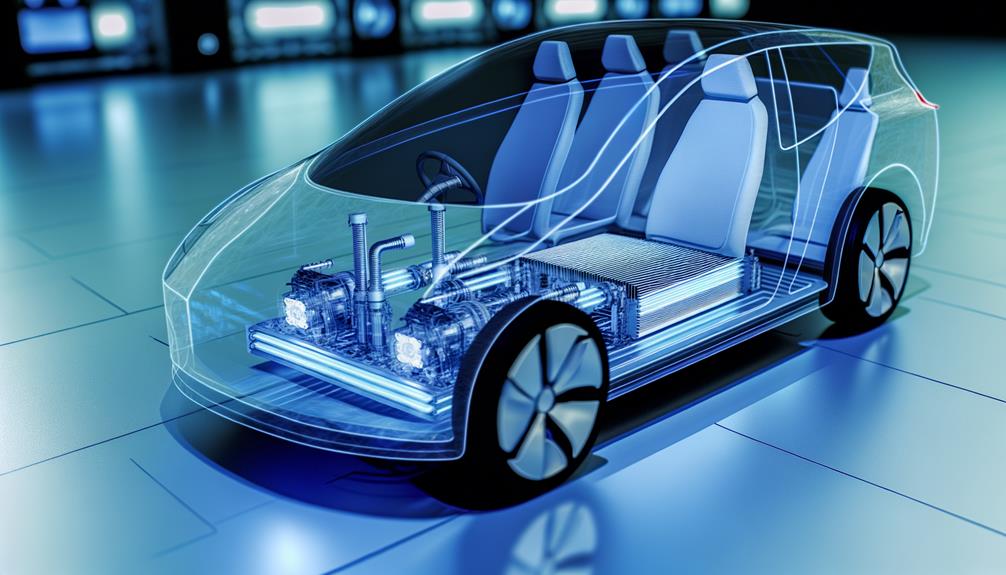

Cooling electric motors is a crucial aspect of electric vehicle design, as these components generate substantial heat during operation. Efficient cooling systems are necessary to maintain ideal performance and prevent overheating. Electric motors require robust thermal management through specialized cooling mechanisms to guarantee they operate within safe temperature ranges.

Modern electric vehicles often employ liquid cooling methods, which involve circulating a coolant through a heat exchanger to absorb and dissipate heat more effectively than air cooling can. This method provides several advantages:

- Enhanced heat dissipation: Liquid cooling systems can remove heat more efficiently, maintaining electric motors at ideal temperatures.

- Dedicated cooling loops: Many EVs feature dedicated cooling circuits for electric motors, guaranteeing consistent temperature control even under high loads or aggressive driving conditions.

- Oil cooling adoption: The use of oil cooling has increased, offering superior heat removal and lubrication. By early 2022, oil cooling systems accounted for nearly 50% of the market.

- Extended component lifespan: Proper thermal management prevents performance degradation and extends the lifespan of electric motors.

- Improved vehicle efficiency: Effective cooling systems enhance overall vehicle efficiency by guaranteeing electric motors operate at their peak performance levels.

The intricacies of thermal management in electric motors are essential for the success of electric vehicles. A well-designed cooling system leverages liquid or oil-based methods to deliver efficient heat removal and maintain stability. By incorporating advanced cooling techniques, manufacturers can guarantee that electric motors run smoothly, efficiently, and with a prolonged lifespan, ultimately enhancing the reliability and performance of electric vehicles.

Liquid Vs. Air Cooling

When comparing cooling systems for electric vehicles, the distinction between liquid and air cooling is vital. Liquid cooling systems, commonly utilized in EVs, circulate a coolant mix of water and ethylene glycol to absorb and dissipate heat from the batteries and power electronics. This method provides a higher heat capacity compared to air cooling, making it more effective in maintaining optimal thermal management and thereby enhancing battery performance and longevity.

Air cooling, on the other hand, is simpler and lighter but lacks the efficiency of liquid cooling. It's often inadequate in maintaining ideal battery temperatures during high-demand scenarios, particularly in hot climates. For instance, the Nissan Leaf, which employs air cooling, has shown limitations in such conditions. Effective thermal management is essential, as it prevents thermal runaway and maintains battery health within the ideal range of 20 to 45 degrees Celsius.

Here's a comparison of the two systems:

| Aspect | Liquid Cooling | Air Cooling |

|---|---|---|

| Efficiency | Higher heat capacity, more efficient | Lower efficiency, particularly in hot climates |

| Complexity | More complex, involving heat exchangers | Simpler system, fewer components |

| Weight | Heavier due to coolant and additional parts | Lighter |

| Battery Performance | Enhances performance and longevity | May reduce performance under high demand |

The shift from air cooling to liquid cooling is gaining traction in the EV market. Manufacturers recognize that robust thermal management is necessary for optimal battery performance and safety. Consequently, liquid cooling is becoming the standard, ensuring that the battery packs remain within their ideal operating temperatures, ultimately extending their lifecycle and reliability.

Radiator Grille Relevance

As the conversation shifts from cooling systems to the relevance of radiator grilles in electric vehicles, it is essential to recognize the distinct thermal management needs of EVs compared to traditional combustion engine cars. Unlike traditional vehicles, electric cars don't require radiators for engine cooling, as they operate without internal combustion engines. This fundamental difference greatly diminishes the practical need for a radiator grille in EVs. Instead, the emphasis is now on optimizing aerodynamic efficiency and brand identity.

Radiator grilles in electric vehicles can still play a vital role, albeit more symbolic or functional in different contexts:

- Aerodynamic Efficiency: Grilles can be designed to enhance airflow around the vehicle, reducing drag and improving energy consumption.

- Brand Identity: Automakers like BMW maintain the presence of grilles to uphold their recognizable aesthetic and brand consistency.

- Heat Dissipation: While not essential for engine cooling, certain grille designs can aid in the dissipation of heat from other components.

- Design Continuity: The grille serves as a visual link between a brand's traditional and electric models, easing consumer change.

- Regulatory Compliance: Some countries have specific design regulations that might influence the inclusion of a grille.

For instance, Tesla and Kia have opted to eliminate grilles from their EV designs, reflecting the reduced necessity for airflow in cooling purposes. This decision underscores their commitment to maximizing aerodynamic efficiency while still maintaining cutting-edge thermal management through alternative methods such as liquid cooling systems. Conversely, BMW's retention of the iconic grille highlights a strategic balance between tradition and innovation.

In essence, the radiator grille's relevance in electric vehicles transcends functional necessity, merging technical advancements with strategic design considerations.

Innovations in Cooling Technologies

You're witnessing a revolution in the thermal management of electric vehicles (EVs), driven by cutting-edge innovations in cooling technologies. One major advancement is the adoption of direct oil cooling systems. These systems not only enhance heat removal but also provide superior lubrication for electric motors, markedly boosting overall performance. By directly cooling the motor windings, these systems guarantee ideal operating temperatures, reducing wear and enhancing efficiency.

Another vital innovation is the implementation of advanced liquid cooling systems. Utilizing a special coolant mix of water and ethylene glycol, these systems effectively manage battery temperatures, maintaining them within a narrow ideal range. This precise thermal management is essential for battery longevity and performance, especially under high-load conditions and rapid charging scenarios.

Researchers are also pushing the envelope with phase change materials (PCMs). PCMs can absorb and release thermal energy, thereby stabilizing the temperature of battery packs and power electronics. This innovative approach helps maintain ideal operating conditions, enhancing both safety and efficiency.

The integration of smart cooling technologies further elevates EV thermal management. Active grille shutters and sensors enable real-time monitoring and adjustment of airflow, optimizing cooling efficiency based on driving conditions and ambient temperatures. This dynamic adjustment improves energy efficiency and extends the range of EVs.

Lastly, ongoing innovations in materials science are resulting in lighter, more efficient cooling components. These advancements contribute to the overall energy efficiency and sustainability of electric vehicles, aligning with the industry's push towards greener technologies. By reducing weight and improving thermal performance, these materials play a pivotal role in the next generation of EV design.

Frequently Asked Questions

Do All Electric Cars Have a Radiator?

You'll find that not all electric cars have traditional radiators. Instead, they use advanced electric vehicle cooling and thermal management systems to regulate battery temperature and guarantee efficient heat dissipation, enhancing overall performance and longevity.

Does a Tesla Have a Radiator?

A Tesla doesn't have a traditional radiator. Instead, Tesla cooling uses a liquid system for thermal management. This advanced design in electric vehicle maintenance enhances radiator function, ensuring peak performance and longevity without conventional radiator components.

Do Electric Cars Need Coolant?

Yes, electric cars need coolant. They use advanced thermal management systems with liquid coolant types to regulate battery temperature and guarantee energy efficiency. Maintaining battery temperatures between 20-45°C is essential for performance, safety, and longevity.

What Runs the Heater in an Electric Car?

In an electric car, the heater's powered by heat pump technology or electric resistance, ensuring efficient cabin heating methods. These systems utilize battery temperature regulation and energy efficiency systems, maintaining ideal performance and warmth regardless of climate.

Conclusion

In summary, electric cars do indeed have radiators, but their role is distinctly different from traditional vehicles. They're essential for thermal management, ensuring batteries, power electronics, and electric motors don't overheat. Advanced liquid cooling systems often outperform air cooling, enhancing efficiency. Radiator grilles, though less prominent, still contribute to this important function. Innovations in cooling technologies continue to evolve, further optimizing performance and longevity. So, while the context has changed, radiators remain a key component in EVs.