When you think about electric cars, you might not immediately consider their weight compared to traditional gasoline vehicles. On average, electric cars are about 30% heavier, largely due to their hefty batteries. For example, the 2023 Ford F-150 Lightning tips the scales at 6,900 lbs, whereas the gasoline version weighs notably less, between 4,021 to 5,013 lbs. This added weight can affect various aspects like vehicle performance and road infrastructure. So, what does this mean for safety, economic implications, and even public perception?

Contents

Understanding EV Weight

Understanding the weight of electric vehicles (EVs) is essential for appreciating their design and performance characteristics. EVs are generally heavier than their gasoline-powered counterparts, primarily due to the substantial weight of the batteries. On average, EVs weigh about 30% more than comparable gasoline-powered vehicles. For instance, the 2023 Ford F150 electric model weighs 6,015 lbs, whereas the gasoline version weighs only 4,060 lbs. This significant difference is largely attributed to the battery, which, in many electric vehicles, averages around 1,000 pounds.

The weight discrepancy is even more pronounced in heavier EVs. The GMC Hummer EV, for example, tips the scales at over 9,000 pounds, with its battery alone contributing approximately 2,900 pounds. Such considerable weight impacts various aspects of vehicle performance, including acceleration, handling, and energy efficiency. The added weight from batteries necessitates robust structural design and advanced engineering solutions to maintain performance standards.

Consumer preference has also played a vital role in the weight dynamics of modern vehicles. There's been a notable shift towards larger vehicles, such as trucks and SUVs, which has increased the average weight for both gasoline and electric vehicles on the road. This trend underscores the importance of understanding the weight characteristics of EVs, especially as they become more prevalent.

The heavier weight of EVs compared to gasoline-powered vehicles is a fundamental aspect of their design. Grasping this concept allows for a deeper appreciation of the engineering challenges and solutions inherent in the development of electric vehicles.

Comparing EVs and Gas Vehicles

When comparing EVs and gas vehicles, you'll notice that EVs are about 30% heavier due to their batteries, which can weigh around 1,000 pounds. For instance, the 2023 Ford F150 Lightning comes in at 6,015 lbs, markedly more than the 4,060 lbs of its gasoline equivalent. This weight disparity influences handling, tire wear, and infrastructure stress, necessitating careful analysis of these impacts.

Weight Differences Explained

Electric vehicles (EVs) generally weigh about 30% more than their gasoline-powered counterparts, with the primary factor being the substantial mass of their batteries. For instance, the 2023 Ford F-150 Lightning EV has a curb weight of 6,900 lbs, whereas the gas-powered model ranges between 4,021 and 5,013 lbs. This significant weight difference is largely due to the EV battery, which on average weighs around 1,000 pounds.

Understanding these weight differences is essential for several reasons:

- Vehicle Handling: Heavier EVs can affect vehicle dynamics, making handling more challenging compared to lighter gas-powered vehicles.

- Efficiency: The increased mass can reduce efficiency, impacting the vehicle's range and energy consumption.

- Stopping Distances: Heavier vehicles generally require longer stopping distances, posing potential safety risks.

- Consumer Trends: There's a notable trend towards larger electric pickups and SUVs, further increasing the average weight of vehicles on the road.

These factors underscore the significant impact of an EV's weight on its performance characteristics and safety profile. As consumer trends shift towards larger electric models, understanding these weight-related implications becomes increasingly important.

Infrastructure Impact Analysis

The infrastructure impact analysis of electric vehicles (EVs) compared to gas vehicles reveals essential insights into road and bridge longevity. EVs typically weigh around 30% more than their gasoline-powered counterparts, primarily due to battery weight. For example, the 2023 Ford F150 electric weighs 6,015 lbs, compared to 4,060 lbs for the gasoline version. This increased EV weight can contribute to road damage and infrastructure strain.

| Vehicle Type | Weight (lbs) | Relative Weight Increase |

|---|---|---|

| Ford F150 Electric | 6,015 | +30% |

| Ford F150 Gasoline | 4,060 | – |

| Heavy Truck | 80,000+ | Significant |

Transportation experts argue that heavy trucks remain the primary contributors to road damage. However, the added weight of EVs may still shorten the lifespan of bridges and necessitate changes in road design. Some states have responded by imposing fees on EV owners to mitigate lost gas tax revenue, which funds road maintenance.

Civil engineers emphasize that future road planning must account for the increasing vehicle weight, both for safety and infrastructure longevity. Fee structures and road maintenance strategies need to adapt to guarantee sustainable infrastructure as EV adoption increases.

Impact on Road Infrastructure

Due to their increased weight, primarily from the substantial battery packs, electric vehicles (EVs) present unique challenges for road infrastructure. EVs typically weigh about 30% more than their gas-powered counterparts. This extra weight, stemming mainly from the batteries, translates to hundreds of additional pounds per vehicle. While heavier vehicles generally contribute to road damage, the overall impact of EVs on road infrastructure is nuanced.

Here are key considerations:

- Comparative Impact: Though EVs are heavier, studies show they cause minimal road damage compared to large transport trucks. A single heavy truck can inflict damage equivalent to thousands of cars, including EVs.

- Rural Road Vulnerability: Rural roads may face challenges supporting the additional weight of heavier passenger vehicles, including EVs. The increased load can potentially reduce the lifespan of roads and bridges in these areas.

- Civil Engineering Adaptations: Ongoing discussions in civil engineering stress the need for infrastructure adaptations. This includes reinforcing roads and bridges to accommodate the heavier weight of EVs to maintain road safety and longevity.

- Maintenance Considerations: While the weight of EVs does add to road wear, the maintenance impact is relatively minor compared to heavy transportation vehicles. Nevertheless, regular maintenance and monitoring of road conditions will be essential as the prevalence of EVs increases.

Economic Implications of EV Weight

As you consider the economic implications of EV weight, note that increased maintenance costs arise from the additional stress heavier vehicles place on road infrastructure. With EVs making up 7% of new vehicle sales in 2022 and projected to reach 67% by 2032, states are already compensating for reduced gas tax revenue by imposing higher registration fees. This shift underscores the financial adjustments required to sustain road maintenance in an era of growing EV adoption.

Increased Maintenance Costs

Electric vehicles (EVs), with their 30% greater weight compared to gasoline-powered counterparts, place a significant strain on road infrastructure, leading to increased maintenance costs. The additional weight of EVs accelerates wear and tear on road surfaces, necessitating more frequent repairs and consequently elevating maintenance costs. This phenomenon is particularly evident with larger and heavier vehicles which exacerbate pavement damage.

To address these issues, some states have introduced annual fees for EV owners. For instance, Alberta has proposed a $200 tax to help offset the additional maintenance costs attributed to heavier vehicles. This approach aims to guarantee that the funding sources for road upkeep are equitable across different vehicle types.

Here are key considerations:

- Pavement Damage: Heavier EVs contribute to increased pavement damage, necessitating higher maintenance budgets.

- Annual Fees: States like Alberta propose annual fees to distribute the financial burden of road maintenance more fairly.

- Wear and Tear: The accelerated wear and tear from heavier EVs requires more frequent infrastructure repairs.

- Funding Sources: As EV adoption grows, funding sources for road maintenance may need reevaluation to guarantee all vehicle types contribute equitably.

Understanding these factors is vital for policymakers and engineers to plan sustainable and economically viable infrastructure.

Reduced Gas Tax Revenue

The shift toward electric vehicles (EVs) greatly disrupts traditional revenue streams from gas taxes, a primary source for funding road maintenance. As EV adoption increases, gas tax revenues—essential for road maintenance—decline because EVs do not contribute to these taxes. This revenue loss has prompted 33 states to impose fees on EV owners to offset the deficit.

For instance, Tennessee has implemented the highest annual EV fee of $274, acknowledging the need to compensate for lost gas tax income. The weight of EVs, typically 30% heavier than their gasoline counterparts, exacerbates infrastructure costs. Heavier vehicles accelerate road wear, necessitating more frequent and costly repairs. As experts highlight, road maintenance costs are markedly influenced by vehicle weight, making the heavier EVs a notable concern.

The Biden administration's goal for 67% of new passenger-car sales to be EVs by 2032 raises further questions about sustainable funding for road infrastructure. Without substantial gas tax revenue, alternative funding mechanisms, such as EV-specific fees, are essential to address the increased infrastructure costs and maintain road quality. As the EV market expands, balancing revenue streams and road maintenance demands will be crucial.

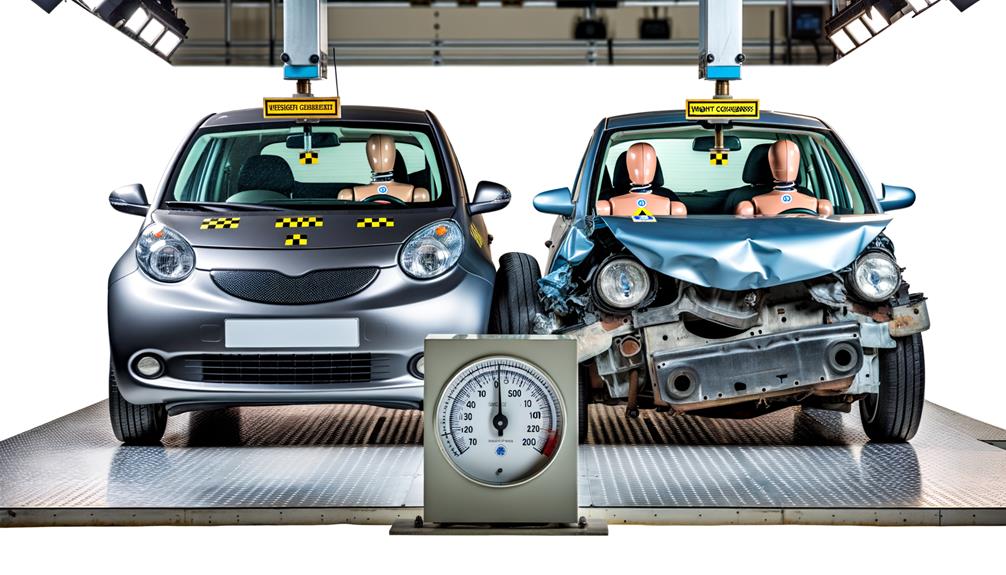

Safety Concerns With Heavier EVS

With the increasing weight of electric vehicles (EVs), there are significant safety concerns that merit attention. Heavier EVs can escalate the risk of fatalities in collisions. For every additional 1,000 pounds of vehicle weight, the probability of fatalities rises by 47%. This stark statistic underscores the gravity of the situation.

Notably, the National Bureau of Economic Research highlights that passengers in lighter vehicles face increased dangers during crashes with heavier EVs. This discrepancy in vehicle weight raises substantial safety concerns for occupants of smaller cars. To further elucidate these risks:

- Pedestrians and Cyclists: Heavier vehicles, including EVs, pose a greater threat to pedestrians and cyclists. Studies have shown a troubling trend of increasing pedestrian and roadway fatalities linked to heavier vehicles.

- Infrastructure: Civil engineers are voicing concerns about the impact of the weight of modern EVs on current infrastructure. There's a pressing need to reevaluate safety regulations and design parameters to adequately support the heavier loads of these vehicles.

- Fatalities: According to the Insurance Institute for Highway Safety, there's a direct correlation between increased vehicle weight and higher fatality risks in crashes. This is particularly evident in light trucks and SUVs, which now include many heavier EV models.

- Collisions: Heavier EVs create a disproportionate risk profile in collisions. The augmented force exerted during impacts can lead to more severe outcomes for all parties involved, especially those in lighter vehicles.

Innovations in Vehicle Design

While addressing the weight challenges of electric vehicles (EVs), innovations in vehicle design are making noteworthy strides. Engineers and designers are focusing on integrating batteries directly into the vehicle's structure, a move that enhances structural integrity without adding undue weight. This integration guarantees that the battery pack serves dual purposes: energy storage and structural support, thereby optimizing the vehicle's overall weight distribution and safety.

Advances in battery technology are vital. By improving energy density, manufacturers can develop lighter batteries that deliver equivalent or superior power compared to their heavier predecessors. This advancement translates to a considerable reduction in the overall weight of EVs, thereby enhancing performance and efficiency.

Material science is playing a significant role as well. Researchers are exploring the use of lightweight composites and advanced alloys to replace traditional, heavier materials. These innovations in materials science not only reduce weight but also maintain, or even enhance, the vehicle's structural integrity and safety standards.

Additionally, the development of modular battery systems is gaining traction. These systems allow for the swapping or upgrading of battery packs, which can mitigate the weight burden associated with older, less efficient battery technologies. This modular approach offers a flexible, future-proof solution to weight management in EVs.

Aerodynamics is another essential focus area. Streamlined designs with optimized aerodynamic profiles can greatly improve an electric vehicle's efficiency by reducing drag. Enhanced aerodynamics, combined with lightweight materials and advanced battery technology, address performance challenges linked to weight, ultimately leading to more efficient and high-performing EVs.

Public Perception and Policy

Innovations in vehicle design aren't just about enhancing performance and efficiency; they also influence public perception and policy development regarding electric vehicles (EVs). The perception that EVs are heavier than gas cars often brings concerns about increased road wear and safety. However, data shows that heavy trucks, not passenger vehicles, are the primary culprits of road damage. Despite this, public discourse often overlooks these facts, focusing instead on the perceived risks of heavier EVs.

As the adoption of EVs grows, states have begun to address the decline in fuel tax revenue. Traditionally, fuel taxes have funded road maintenance, but EVs, which don't rely on gasoline, sidestep these taxes. To compensate, several states have implemented fees on EV owners, leading to significant variability. For instance, Tennessee charges $274 annually, a figure that has sparked debate over its fairness.

Critics argue that flat fees for EVs don't consider mileage or vehicle weight, resulting in inequitable contributions to road maintenance. This debate underscores the need for more nuanced policy approaches, such as mileage-based fees, which could guarantee a fairer distribution of road maintenance costs.

Public perception is further complicated by misinformation about the safety risks posed by heavier EVs. Accurate education on this topic is essential to dispel myths and inform policy decisions. To summarize the key points:

- Road Damage: Heavy trucks cause more wear and tear than passenger vehicles, including EVs.

- Revenue Replacement: States are introducing EV fees to offset declining fuel tax revenues.

- Fairness Debate: Flat fees may result in inequitable contributions to road maintenance.

- Policy Evolution: Mileage-based fees could offer a more equitable funding solution.

Understanding these dynamics is essential for developing informed, equitable policies that reflect the realities of EV usage and its impact on infrastructure.

Frequently Asked Questions

How Much Heavier Is an Electric Car Than a Regular Car?

Electric cars are typically 30% heavier than regular cars due to battery weight. This affects vehicle efficiency, design considerations, range limitations, material differences, performance factors, cost implications, safety ratings, charging infrastructure, and environmental impact.

Are Tesla Cars Heavier Than Gas Cars?

Yes, Tesla cars are heavier than gas cars. The Tesla weight comparison shows battery impact as a key factor. Despite performance differences, safety ratings, charging infrastructure, maintenance costs, resale value, driving range, and environmental impact influence consumer preferences.

Are Electric Cars Too Heavy for the Roads?

You're right to ask about road safety with heavier electric cars. Weight distribution impacts load capacity, suspension systems, and braking performance. Proper tire pressure and driving dynamics are essential. Infrastructure adaptation is necessary for long-term impact resistance and environmental considerations.

Do Electric Cars Wear Out Tires Faster?

Yes, electric cars wear out tires faster due to increased weight distribution and load capacity. However, driving habits, tire technology, road conditions, tire pressure, regenerative braking, and electric vehicle maintenance also greatly impact tire wear and performance.

Conclusion

To summarize, electric vehicles (EVs) indeed weigh considerably more than their gasoline counterparts, primarily due to battery mass, with models like the 2023 Ford F-150 Lightning illustrating this trend. This increased weight impacts stopping distances, vehicle performance, and road infrastructure, particularly in rural areas. Furthermore, the economic implications and safety concerns necessitate innovative design solutions. Policymakers and the public must consider these factors to effectively integrate EVs into the transportation ecosystem.