When you're considering why electric cars come with such hefty price tags, it's important to understand the primary factors driving these costs. High battery technology expenses, which can make up a significant portion of an EV's price, are influenced by volatile raw material costs and intricate manufacturing processes. But that's just scratching the surface. Investments in research and development for safety, efficiency, and performance enhancements also play a vital role. Curious about how advanced technology and market dynamics further impact the pricing? There's much more to uncover.

Contents

Battery Technology Costs

When delving into battery technology costs, it's essential to recognize that these expenses considerably influence the overall pricing of electric vehicles. Battery technology is a vital factor, particularly since the cost of lithium-ion batteries remains substantial despite significant price reductions over the past decade. In fact, the average cost of an EV battery in 2023 was around $5,500, illustrating how these components still account for a significant portion of an electric vehicle's price.

The high costs associated with lithium-ion batteries stem from the expensive raw materials such as lithium, cobalt, and nickel. These materials are not only costly but also subject to market volatility, further complicating cost management. Additionally, the intricate manufacturing processes required to produce high-quality batteries contribute to the elevated costs. These processes demand precision engineering and sophisticated technology, which are inherently expensive.

Moreover, the substantial research and development (R&D) investments needed to enhance battery technology add to the overall expense. The relentless pursuit of advanced battery technology that delivers longer ranges and faster charging times necessitates significant financial resources. These R&D efforts are vital for meeting consumer expectations and improving vehicle performance but inevitably increase the upfront costs of electric vehicles.

Battery efficiency and lifespan are also significant factors influencing costs. As manufacturers work to improve these attributes, they must allocate substantial funds toward ongoing advancements in battery technology. These enhancements guarantee that EVs offer competitive performance and durability, but they also mean higher initial expenses for consumers. To summarize, the intricate interplay of raw material costs, manufacturing complexities, and R&D investments make battery technology a major cost driver in the electric vehicle market.

Economies of Scale

Battery technology costs greatly affect the pricing of electric vehicles, but another major factor to contemplate is economies of scale. Right now, electric cars have a limited production volume, with only about 1 million EVs on the road in the U.S. compared to over 250 million internal combustion engine (ICE) vehicles. This disparity prevents the cost savings that come from economies of scale, directly impacting consumer prices.

Because the production scale of EVs is still ramping up, manufacturers can't achieve the same cost reductions per unit that traditional vehicles have enjoyed. ICE vehicles benefit from a century-long history of established manufacturing processes and extensive supply chains. In contrast, the nascent electric car industry faces higher initial production costs due to limited economies of scale. These high costs are then passed on to consumers, making EVs more expensive.

However, as the market for electric vehicles grows, increased production volumes are expected to improve cost efficiency. Higher production volumes enable manufacturers to spread fixed costs over more units, leading to lower per-unit costs. This improvement in cost efficiency will eventually translate to lower prices for consumers, making EVs more competitive with traditional vehicles.

To accelerate this process, government incentives and subsidies have been implemented to stimulate EV adoption. These measures aim to offset the high initial production costs, encouraging both manufacturers and consumers to invest in electric vehicles. But until the production volumes reach a critical mass, the lack of extensive supply chains and established manufacturing processes will continue to contribute to the higher per-unit costs of electric cars.

Research and Development

You'll notice that significant investment in research and development is essential for enhancing the safety, efficiency, and performance of electric vehicles, directly impacting their initial costs. Since the historical data on optimizing EVs is limited compared to internal combustion engine vehicles, manufacturers face higher R&D expenditures to develop effective technologies. Additionally, the integration of advanced features like battery management systems and electric drivetrains necessitates ongoing innovation, further driving up R&D expenses and, consequently, the consumer prices of electric cars.

Innovation Cost Drivers

The research and development (R&D) phase for electric vehicles (EVs) greatly drives up their initial costs, as manufacturers need to invest heavily to enhance performance, safety, and efficiency. To innovate in EV technology, substantial resources are directed toward developing advanced battery management systems and electric motors. These components are complex and require extensive research to optimize, leading to elevated R&D expenses.

Given the limited historical data on EV optimization, continuous R&D is essential to establishing best practices and refining production processes. This ongoing need for research translates into higher manufacturing costs. Additionally, R&D efforts often lead to the development of innovative features like advanced driver-assistance systems (ADAS) and cutting-edge infotainment technologies, which further inflate the cost of production.

Manufacturers also face the challenge of meeting ever-evolving consumer demands for longer ranges and faster charging capabilities. Addressing these demands necessitates relentless R&D, adding to the financial burden. Therefore, while innovation and technology advancements are vital for the growth of the EV market, they also greatly contribute to the high initial costs of electric vehicles.

Efficiency Optimization Efforts

In recent years, significant investments in research and development (R&D) have been vital in enhancing the efficiency of electric vehicles (EVs). These efforts focus on refining key components, particularly battery technology, to improve driving range and reduce costs. Advancements in lithium-ion batteries, for instance, are important as they directly impact the efficiency and affordability of EVs. However, the complexity of developing such advanced systems also leads to higher manufacturing costs.

You'll find that substantial R&D funding is required to refine electric motors and battery management systems. These components are essential for achieving peak performance and efficiency in EVs. The integration of innovative features, such as state-of-the-art infotainment systems, further drives up R&D expenditures. These cutting-edge technologies, while beneficial, contribute to the higher initial pricing of electric vehicles.

Moreover, the limited historical data on EV refinement compared to traditional vehicles means manufacturers have to invest more in R&D to enhance these technologies. This ongoing research is necessary to guarantee that EVs become more efficient and cost-effective over time. Ultimately, while these R&D efforts increase the initial costs of electric vehicles, they are vital for long-term efficiency enhancement.

Advanced Safety Features

While efficiency optimization remains a pivotal aspect of EV development, another essential area demanding considerable R&D investment is the integration of advanced safety features. Electric vehicles often come equipped with advanced driver-assistance systems (ADAS) and other cutting-edge safety mechanisms. These high-tech safety systems require extensive research and development, greatly driving up the production expenses.

The complexity of integrating features like automatic emergency braking and lane-keeping assist necessitates rigorous testing and validation. This guarantees consumer safety but also adds to the initial pricing of electric cars. As manufacturers prioritize consumer safety, the need for continuous innovation in safety technologies becomes imperative. This ongoing R&D funding indirectly influences the cost of EVs, making them more expensive.

Market demand for superior safety features has led to competitive pressure among manufacturers. Companies are compelled to invest heavily in R&D to offer the latest advancements, escalating costs further. This competitive landscape assures that only the most innovative and safest vehicles make it to market, but it also means that these investments contribute to the higher price tags of electric cars. Fundamentally, the push for advanced safety features is a critical factor in the overall expense of EVs.

Advanced Technology

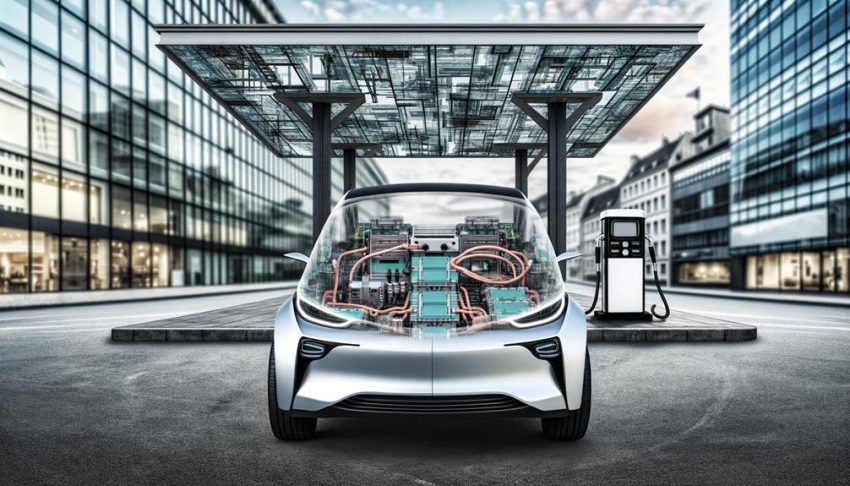

Charting the landscape of electric vehicle (EV) pricing, you'll see that advanced technology plays a vital role in driving up costs. Electric vehicles integrate a plethora of advanced technologies, such as electric motors and sophisticated battery management systems. These components are not only intricate but also costly to manufacture. The complexity inherent in these systems greatly increases manufacturing costs, which are directly reflected in the purchase price.

Furthermore, high-tech features like advanced driver-assistance systems (ADAS) and cutting-edge infotainment systems contribute considerably to the overall pricing of EVs. These innovations necessitate extensive research and development, driving up costs even before production begins. The considerable investment required to develop these technologies translates to higher initial prices for consumers.

In addition, the specialized production techniques essential for manufacturing EVs necessitate new machinery and rigorous training programs. Traditional automotive manufacturing processes simply don't suffice for EVs, leading to increased operational costs. These additional expenses are inevitably passed on to the consumer, further elevating the purchase price.

Consumer demand for high-tech features in EVs also plays a vital role. As more consumers seek out the latest in technology, manufacturers are compelled to continuously invest in new advancements. This perpetual cycle of innovation and development adds another layer of cost, contributing to the higher prices of electric vehicles.

While the costs associated with advanced technology are considerable, they may decrease as the technology matures and becomes more widespread. For now, however, the sophisticated systems and specialized techniques required for EV production remain a primary factor in their high purchase price.

Market Dynamics

When considering market dynamics, you'll notice that supply chain challenges and fluctuating demand greatly impact EV pricing. Manufacturers like Chevrolet and Hyundai adjust their strategies, lowering prices on entry-level models to stay competitive, while high-profile models often incur surcharges. Despite an 18% rise in EV registrations, limited production volumes and ongoing R&D investments contribute to higher costs compared to traditional gasoline vehicles.

Supply Chain Challenges

Supply chain challenges have become a notable factor driving up the costs of electric vehicles (EVs). You've probably noticed that production costs for EVs are much higher, primarily due to bottlenecks in the supply of essential raw materials like lithium, cobalt, and nickel. These materials are critical for batteries, which account for about 75% of an EV's cost. When there are raw material constraints, it directly impacts manufacturing costs, making it difficult for producers to maintain competitive pricing.

The global semiconductor shortage has also exacerbated these supply chain challenges, leading to delays and further increasing production costs. As a result, market adjustments often include surcharges that push the price of new EV models even higher. Despite advancements in battery technology, these supply chain issues mean you're still paying notably more for an EV—around $12,000 more than a gasoline vehicle.

These elevated costs are not just due to raw materials but also the complex logistics and market dynamics involved. Manufacturers are continually adapting to these challenges, but until supply chain stability is achieved, the high cost of EVs will likely persist.

Pricing Strategy Variations

While electric vehicle (EV) manufacturers navigate a complex market, their pricing strategies vary considerably, reflecting a diverse landscape driven by different brand positions and consumer segments. Mainstream brands often adopt competitive pricing for entry-level models to attract a broader audience. For instance, Chevrolet and Hyundai have reduced prices on certain models to drive adoption. Conversely, luxury brands leverage advanced technology and premium features to justify higher prices, targeting affluent consumers.

As of mid-2023, the average price of an electric car remains about $12,000 higher than that of gasoline vehicles. This gap is partly due to persistent supply chain issues and fluctuating market demand. Some high-profile models even face market adjustment surcharges, further escalating their costs.

New EV models enter the market with diverse pricing strategies, reflecting differences in features, technology, and brand positioning. This creates a varied pricing landscape where consumers have multiple options based on their preferences and budget.

Predictions suggest the price gap between electric and gasoline vehicles will narrow as production scales up and market demand evolves. This shift could lead to more competitive pricing, making electric cars more accessible to a wider audience in the near future.

Cost of Ownership

The cost of ownership for electric vehicles (EVs) is a vital factor to evaluate, especially given the initial higher purchase price compared to gasoline vehicles. Despite this higher initial cost, EVs often offer considerable savings over the total cost of ownership. A key reason for this is the substantial reduction in fuel costs. On average, you'll spend about $485 annually on electricity for an EV, compared to $1,117 for gasoline, reflecting around 60% savings on fuel expenses.

Maintenance costs also play a significant role in lowering the total cost of ownership. EVs have fewer moving parts and lack components such as spark plugs and oil filters, which means they generally require fewer repairs and less frequent servicing. Fundamentally, you can expect EV maintenance costs to be about half of what you'd pay for a gas vehicle. This reduction in maintenance needs directly converts to cost savings over the long run.

Tax credits and incentives further enhance the affordability of EV ownership. Federal rebates, which can go up to $7,500 for new EVs, greatly reduce the initial cost, making the shift to electric more financially feasible. These incentives make a noticeable difference in the upfront investment required, thereby improving the overall cost-benefit ratio of owning an EV.

When you take into account the lower ongoing expenses, including potential savings from home charging, it becomes clear that the total cost of ownership for EVs is economically advantageous in the long run. So, while the initial purchase price might be intimidating, the accumulated savings in fuel and maintenance costs, coupled with tax credits, make EVs a smart financial choice over time.

Barriers to Adoption

Despite the economic benefits of owning an electric vehicle (EV), several barriers continue to impede widespread adoption. One of the most significant hurdles is the initial purchase price. With the average EV price being approximately $12,000 higher than gas vehicles as of mid-2023, many consumers find electric cars so expensive that they hesitate to make the switch. This higher upfront cost can be a major deterrent, especially when compared to traditional vehicles.

Another barrier is the limited charging infrastructure. While progress has been made, the convenience of refueling a gasoline car still surpasses that of charging an EV. Longer charging times exacerbate this issue, contributing to range anxiety, where potential buyers worry about the vehicle's ability to travel long distances without frequent recharging stops.

| Barrier | Impact |

|---|---|

| High Initial Cost | Average EV price $12,000 higher than gas vehicles |

| Charging Infrastructure | Limited availability and longer charging times |

| Range Anxiety | Concerns about vehicle's travel distance on a single charge |

| Insurance Costs | 25.5% higher than for internal combustion engine vehicles |

| Resale Value | Uncertainty about resale value compared to traditional vehicles |

Insurance costs for EVs also play a role in their adoption. On average, insurance premiums for electric cars are about 25.5% higher than for internal combustion engine vehicles, adding to the overall cost of ownership. Finally, concerns about the resale value of EVs compared to traditional vehicles can make consumers hesitant. The perceived uncertainty in the resale market may deter potential buyers from committing to an electric vehicle.

Frequently Asked Questions

Why Are Electric Cars Too Expensive?

You're finding electric cars expensive due to high battery production costs, limited economies of scale, and advanced technology. However, government incentives, long-term savings, and improving charging infrastructure could offset initial expenses, enhancing resale value and market demand.

Are Electric Cars Ever Going to Get Cheaper?

Yes, electric cars are expected to get cheaper. Future predictions suggest that advancements in battery technology, government incentives, increased market competition, reduced manufacturing costs, a streamlined supply chain, rising consumer demand, and environmental impact awareness will lower prices.

Why Do Electric Cars Cost More Than Gas?

Electric cars cost more than gas vehicles due to expensive battery technology, higher production costs, supply chain complexities, and limited market demand. Government incentives, resale value, and lower maintenance costs don't fully offset consumer perception of high upfront prices.

Do Electric Cars Increase Your Electric Bill?

Yes, electric cars do increase your electric bill, but charging costs are often offset by lower overall expenses due to energy efficiency. Home installation and usage patterns, along with local rates and government incentives, lead to significant long-term savings.

Conclusion

To summarize, electric cars are pricey largely due to high battery technology costs, compounded by volatile raw material prices and complex manufacturing. Limited economies of scale and substantial R&D investments further inflate costs. Advanced technology integrations and ongoing supply chain issues also play key roles. While these factors currently elevate prices, continued advancements and increased production volumes should gradually lower costs, making EVs more accessible in the future.